Making Ever-better Cars – Mobility

June 13, 2022

Toyota is implementing structural innovation across our global car-making business to make ever-better cars. We are changing the basic architecture of our cars to greatly enhance basic performance and product appeal through Toyota New Global Architecture (TNGA).

TNGA is a program of structural innovation, starting with changing the basic architecture of vehicles. Through TNGA, we are completely remaking the powertrain unit (engine, transmission, HEV unit) and basic frames (chassis). With integrated product development we anticipate a rapid improvement in the three areas of driving basic performance, namely, moving, turning, and stopping. We hope to continue to provide cars that our customers cherish.

The idea of TNGA cycle underlies the improved basic and product performance of Well-built Cars while incorporating smart sharing that considers total optimization, and promotes Smart Monozukuri (manufacturing) in collaboration with suppliers and production sites. This initiative has enabled reduction in development resources and reinvestment of reserves to improve quality and product performance, leading to a timelier delivery of ever-better cars.

Product-based Company System to create Distinctive Appealing Cars

Toyota has adopted a product-based in-house company system to enhance fundamental design, wishing to draw attention from our customers and improve basic performance to provide an experience that makes drivers want to keep on driving. We are also aiming for total optimization by pursuing smart sharing, thereby improving efficiency, and reducing costs. These efforts are greatly increasing our potential to create aisha, which in Japanese means “cars that will be beloved by customers.” Building on the foundation provided by TNGA, the in-house companies consider market needs and consumer preferences in each region to craft distinctive, appealing cars that customers will love.

One specific initiative under TNGA is the development of new powertrains, which form the core of the automobile. New powertrains have a lower center of gravity, promoting both excellent driving and environmental performance.

Our approach to powertrain development aims to simultaneously enhance product marketability while improving efficiency in production and development. To enhance product appeal, we are working hard to ensure excellent environmental performance, while also seeking to boost driving performance by focusing development on customers’ sensory experiences with the concept of “Direct & Smooth.”

In terms of production efficiency, we are globally unifying processing and assembly standards, as well as process and equipment specifications, in order to create a global architecture that can quickly and flexibly respond to customer needs.

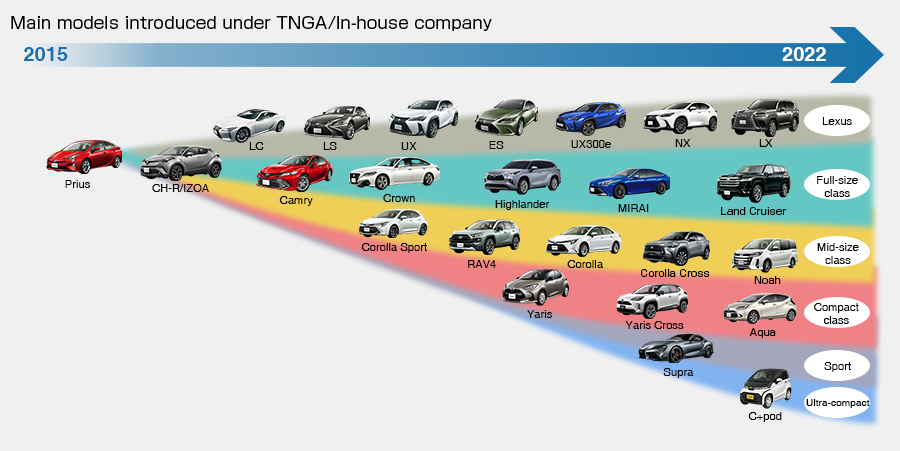

TNGA So Far

Toyota began its TNGA initiatives with the development of the fourth-generation Prius (launched in Japan in December 2015), leveraging the fruits of these initiatives to create other models including the medium-sized “Corolla,” the large “Crown,” “Lexus LS,” and the compact “Yaris.” These initiatives were applied to 41 models as of March 2022, and approximately 70% of global sales have been switched to new models. While all these models share TNGA components, the character of each is completely distinct, as is immediately apparent in terms of design and ride experience. The in-house companies have created these cars to suit different customer preferences so that every customer can find a car they love.